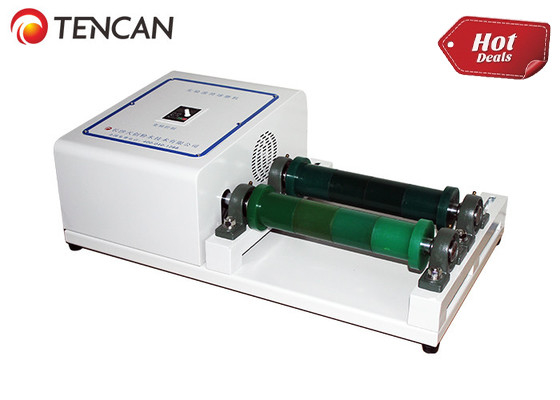

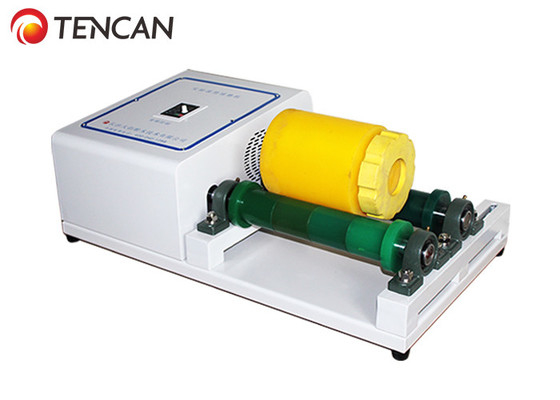

Controllo della frequenza 5L Roll Ball Mill Compatto sistema di rettifica bagnato/seco con uscita uniforme di polvere e velocità di rotazione 60-570 RPM

Dettagli:

| Luogo di origine: | Hunan, Cina |

| Marca: | TENCAN |

| Certificazione: | CE ISO |

| Numero di modello: | QM-5 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 set |

|---|---|

| Prezzo: | Negoziabile |

| Imballaggi particolari: | Carton+Foam |

| Tempi di consegna: | 3-7 giorni lavorativi dopo avere ottenuto pagamento completo |

| Termini di pagamento: | T/T, Western Union |

| Capacità di alimentazione: | 300 serie al mese |

|

Informazioni dettagliate |

|||

| nome del prodotto: | Lavorazione di mini mulini a sfera a rotoli | Modello N.O.: | QM-5 |

|---|---|---|---|

| Voltaggio: | 220V-50Hz o 110V-60Hz | Potenza: | 0.37KW |

| Velocità di rotazione: | 60-570 giri/min. | Controllo della velocità: | Controllo della frequenza |

| Volume totale: | 5L | Capacità massima: | 1.65L |

| Evidenziare: | Collettore a sfere a rotoli di uscita uniforme di polvere,Sistema di triturazione a secco/umido compatto,mulino a palle del rotolo 5L |

||

Descrizione di prodotto

Parametri tecnici

| Parametro tecnico del mulino a sfere di laboratorio a mini rotoli | ||||||||

| Numero modello. | QM-5 | QM-15 | ||||||

| Dimensioni/Peso netto | 730*415*260mm/32KGS | 840*435*270mm/43KGS | ||||||

| Potenza del motore | 0.37kw | 0.75kw | ||||||

| Specifiche del convertitore di frequenza | 0.4kw/220v | 0.75kw/220v | ||||||

| Velocità di rotazione | 60-570r/min±10rpm | 60-570 rpm±10 rpm | ||||||

| Spazio regolabile tra i rulli | 120 mm | 140 mm | ||||||

| Carico massimo per barattolo | 35KGS | 80KGS | ||||||

| Dimensioni dei barattoli macchiati | 0.5-5L | 10-15L | ||||||

Disponibili barattoli da mulino:

Bottine di acciaio inossidabile 304, bottine di acciaio inossidabile 316, bottine di carburo di tungsteno, bottine di agate, bottine di alluminio ceramiche (chiamate anche bottine di corindone), bottine di zirconia, bottine di nylon,contenitore di poliuretano, barattoli di molino (PTFE), ecc.

![]()

| Raccomandazione per la corrispondenza delle soluzioni relative ai vasi e ai materiali del mulino | |

| Categorie di materiali | Vaso per mulino consigliato |

| Terreno e altri materiali che non sono ammessi con alcuna impurità | Acciaio di acciaio |

| Materiali metallici e non metallici che non sono ammessi con alcuna impurità | Bottine da mulino di zirconia |

| Materiali ad alta durezza come diamanti, carburo di tungsteno | Fabbricazione a partire da prodotti della voce 8528 |

| Materiali a forte aggiunta e alcalini o altri materiali ad alta temperatura | Bottine di PTFE |

| Materiali di minerale di ferro con minore sensibilità alle impurità | Fabbricazione in acciaio |

| Pigmenti o altri materiali con processo successivo ad alta temperatura | Fabbricazione a partire da prodotti della voce 8528 |

| Materiali di alluminio come la glassa ceramica | Fabbricazione a partire da semi di legno |

| Materiali elettronici come batterie al litio | Fabbricazione a partire da prodotti della voce 8528 |

| Materiali facilmente ossidati o alcuni materiali speciali che devono essere essere protetti in una atmosfera speciale. |

Bottine per mulini a vuoto |

Disponibili sfere di mulino:

304 sfere di fabbrica di acciaio inossidabile, 316 sfere di fabbrica di acciaio inossidabile, sfere di fabbrica di carburo di tungsteno, sfere di fabbrica di agate, sfere di allumina, sfere di fabbrica di zirconia, ecc.

![]()

| Riferimenti sui mezzi e i materiali di macinazione | ||

| Materiali di Mezzi di macinazione |

Durezza (Mohs) |

Caratteristiche |

| Pelle di zirconia | ≥ 90 | Super resistenza all'usura, senza impurità, corrosione e resistenza alle alte temperature. |

| Pelle di acciaio inossidabile | ≥ 60 | Resistenza all'usura, resistenza alla corrosione generale, resistenza alle alte temperature. |

| Giochi d'agata | ≥ 7.0 | Super resistente all'usura, utilizzato per medicinali, alimenti e altri materiali che non possono essere contaminati da metalli, resistenti alla corrosione e ad alte temperature. |

| Pelle di alluminio | ≥ 85 | Resistenza all'usura, resistenza alla corrosione e resistenza alle alte temperature. |

| Calzature di carburo di tungsteno | ≥ 90 | Super resistenza all'usura, senza impurità, corrosione e resistenza alle alte temperature. |

| Soluzioni di abbinamento per barattoli e palline da mulino | |||||

| Articolo 2 | Giochi d'agata | Pelle di alluminio | Pelle di acciaio inossidabile | Pelle di zirconia | Calzature di carburo di tungsteno |

| Agate Mill jar | √ | ||||

| Bottine da mulino di corindono | ▲ | √ | ▲ | ||

| Bottine di acciaio inossidabile | √ | ||||

| Barattoli da mulino di zirconia | ▲ | √ | |||

| Bottine da mulino di nylon | ▲ | √ | |||

| Bastone per mulino in PTFE | √ | ▲ | |||

| Fabbricazione a partire da prodotti della voce 8528 | √ | ▲ | |||

| Carboidrati di tungsteno | ▲ | √ | |||

| √ significa: più adatto ▲ significa: adatto | |||||